Our Technologies

Mecom Srl, thanks to its machines, can realize mechanic workings such us turning, milling, drilling made by bars (round or tubes) but also by fusions or by moulds. Mecom srl has a strong experience in metal working and it uses a wider range of materials: titanium, inconel, cronidur, 15.5-PH, avional, aluminium, brass, over than the most common 100Cr6, 100CrMo7, 42CrMo4.

Layout and Equipment

Mecom Srl has next-gen CNC multitasking machines and a multi-mandrel machine with mechanical stoker that offers a great flexibility in the production of whatever batch, from few units to thousands of pieces.

We have chosen to have state-of-the-art machines and monitoring systems that allow the realization of high quality products

Mecom Srl has also a cutting area, an area for the adjustment and the manual de-burring more than an area dedicated to the production of the supplies to facilitate the production.

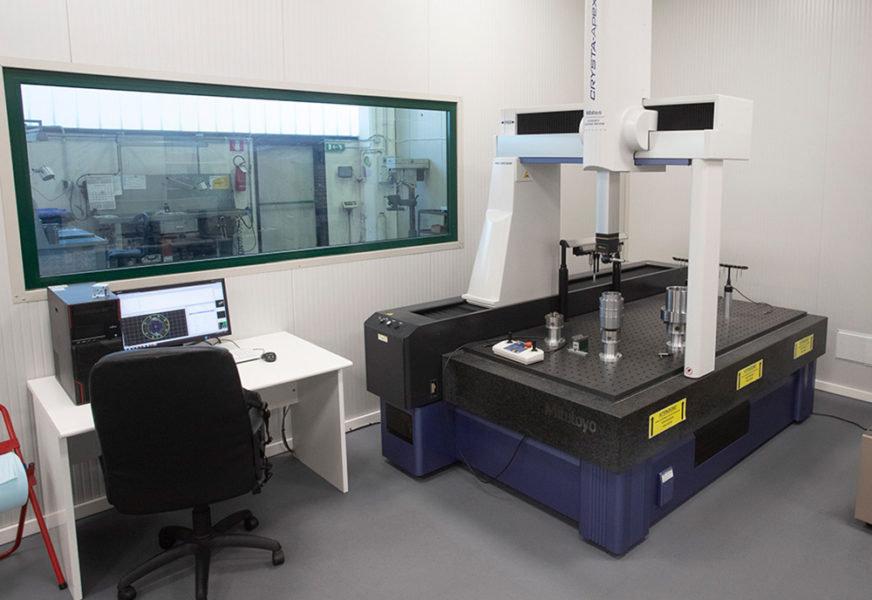

The company, in addition to measurement instruments that are essential for the control of the components (roughness meters, profilometers…), has a metrological room that gives assistance to the production. It can also make mechanical marking of progressive numbers.

The company has an innovative robot warehouse that allows to excellently manage the tools necessaries for the production.

Equipments

INTERACTIVE MANUFACTURING SYSTEM

Mecom Srl has an Interactive Manufacturing System composed of wireless touchscreen on the machines for the organization of the production that efficiently interacts with the staff of the productive department and the rest of the company

The system has electronic files that interface with the machines to detect the state, the quantity that has been produced and to send and receive the part-program. Every work cycle has its own control plans, tools and instruments schedules to revise the production